Dry Scrubber

We are leading Dry Scrubber manufacturers in India. Dry Scrubber or dry scrubber system is one type of scrubber that is used to remove harmful materials from industrial exhaust gases before they are released into the environment Dry scrubbers are the type most commonly used in plants today, and they utilize a collection of dry substances to remove acidic gases that contribute to acid rain Dry scrubbers work similarly to other scrubbers The system sprays a collection of dry reagents into an exhaust stream These chemicals can react differently depending on which material they are specifically targeting for removal Some of these materials neutralize harmful pollutants in the stream through a chemical reaction, while others cause a material to react and turn into a different substance That substance then falls out of the gas stream or is caught in a particle screen There are various type of Dry scrubber but we will cover ESP type dry scrubber which is mostly used in commercial kitchen these days

USE

Dry scrubbers are used mainly to remove acid gases from combustion sources Generally, this is done by introducing a series of dry reactants to exhaust gas at high speeds This neutralizes the pollutants in the gas This task is done in three steps gas cooling, reagent injection, and filtering First, gas cooling must be done to prepare exhaust gases In the gas cooling system, emission gases are cooled to make it easier to remove pollutants and other toxins from the gas The exhaust gas is diluted using an evaporative cooler Once the gas has been significantly cooled the reagent injection can begin It is in this step that the harmful components are actually removed from the gas Components of the dry reagent are generally chosen because of their neutralizing properties, thus sodium bicarbonate is frequently included A variety of powders are mixed together and fired at high pressures into the exhaust gas Chemical reactions occur that reduce the acidity of the gas and remove harmful pollutants The final step is using a fabric filter to capture the used scrubbing powder as the cleaned gas exits the scrubbing chamber This spent powder can sometimes be cleansed and reused for dry scrubbing, but frequently it must be disposed since it cannot be properly washed

WORKING PRINCIPLE

ELECTROSTATIC PRECIPITATORS

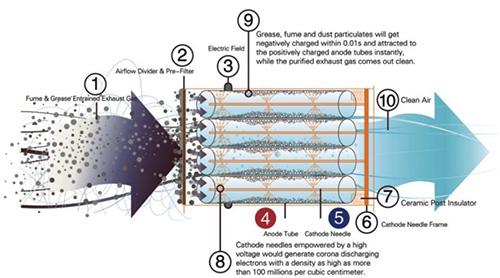

Electrostatic precipitators function uniquely from the different types of industrial scrubbers by using charged energy to remove dust and other contaminates from a gas. It is important to match the polarity and type of charge to bind to and remove the pollutants from the gas. An example of the design of an electrostatic precipitator is a plate precipitator.

The plate is a sheet of metal that is charged with a specific type of charge. These plates are designed to run parallel with the piping so that the gas will pass through by the plates and the plates will remove the dust or contaminate.

In addition to metal plate electrostatic precipitators, there are also wet electrostatic precipitators that help to remove high moisture gases. Some of the chemicals that can be removed from gas include sulfuric acid. The resultant slurry that contains the bound pollutant is rotated away from the electrostatic precipitator to remove the contaminates and maintain an effective charged surface for pollutant removal

- The technology is based on the principle of two stage electrostatic air ltration.

- Fine sub micron suspended particles are electrostatically charged using high voltage electric eld.

- These charged particles get attracted and precipitated on opposite charged electrode plates

HOW IT WORKS?

Electrostatic Dry Scrubber filters the very fine submicron size particles from smoke with high efficiency by ionizing the particles with high voltage. The particles are collected on metallic electrode plates and clean and smoke free air is exhausted out. The filter cells can be cleaned/washed periodically as can be reused for a very long time without any replacement (@10 15 years on an average)

The system is much more compact as compared to wet scrubbers. Also, since the pressure drop is very low the blower power can be saved significantly.

Since this system does not need any water or pump thereof, the running cost of this system is way too small as compared to wet scrubbers.

This system can be coupled with Ultra Violet light system to eliminate the bad odors.

Filteron Modular Series offers the best solution for existing as well as new commercial kitchens. It has wide range of models and any air flow capacity can be built with these models and integrated easily in the systems.

Because of Reliable product with easy and prompt availability of spares and services all over India, Filteron Dry scrubbers are getting approval and acceptance from most of reputed HVAC contractors.

ESP IN KITCHEN

Commercial Kitchen Smoke disposal its management has been a difficult task for facility managers Conventionally, it is exhausted with the help of kitchen hoods Also, just exhausting the fumes will cause so much pollution Wet scrubber is employed as an option to reduce the intensity of these problems However, the removal efficiency of wet scrubber is limited Also, it requires huge amount of power and water Disposal of polluted water brings another challenge.

Electrostatic Precipitator ( based Dry scrubbers provides effective as well as beneficial solution to overcome this daunting problem.

Dry scrubbers is engineered solution for reduction in Smoke, Grease, Odor from the extract of Kitchens and Restaurants through a Scrubber which operates on the principle of electrostatic precipitation It pulls the air through the kitchen hoods and duct into a Dry Scrubber where the fumes are treated before they are exhausted or released into the atmosphere

APPLICATION

- Kitchen Exhaust

- Aerospace Engineering

- Photographic Processing

- Diesel Engines, Gensets, Turbines

- Transmission Rooms

- Compressors, H.V. Alternators

- Power Plants

- Nuclear Fuel Processing Semiconductor Manufacturing

- Disk Drive Manufacturing

- Hybrid Circuits / IC Manufacturing

- Healthcare Facilities Hospitals OTS / ICUS

- Pharmaceutical Manufacturing

TECHNICAL ADVANTAGES

- Stable Transformer Technology

- Filtration Efficiency: Ability of trapping the particles down to 0.01 micron. Equivalent to and better than EU9 grade lters.

- Very Low Pressure Drop: 0.5” of W.C. pressure drop across ESP

- Permanent Filter: ESP never requires any replacement over the lifetime (15 20 years). It only requires periodic cleaning.

- Makes this ideal choice of ne pollutants like oil mist and fumes